As the power battery industry enters the TWh era, the lithium iron phosphate (LFP) system continues to expand its market share due to its high safety and cost advantages. However, the tendency of its nanoscale fine particles to agglomerate has become a key bottleneck restricting manufacturing process upgrades and further improvements in energy density: high slurry viscosity, difficulty in increasing solid content, and susceptibility to cracking under high-speed, thick coating—these pain points directly drive up production costs and limit the performance boundaries of batteries.

In response to this common industry challenge, MANST has launched the Sparsux216 positive electrode slurry dispersant. Starting from micro-interface chemistry and applied to macro-manufacturing processes, it broadens the process window, steadily empowering cost reduction, efficiency improvement, and performance breakthroughs in battery manufacturing.

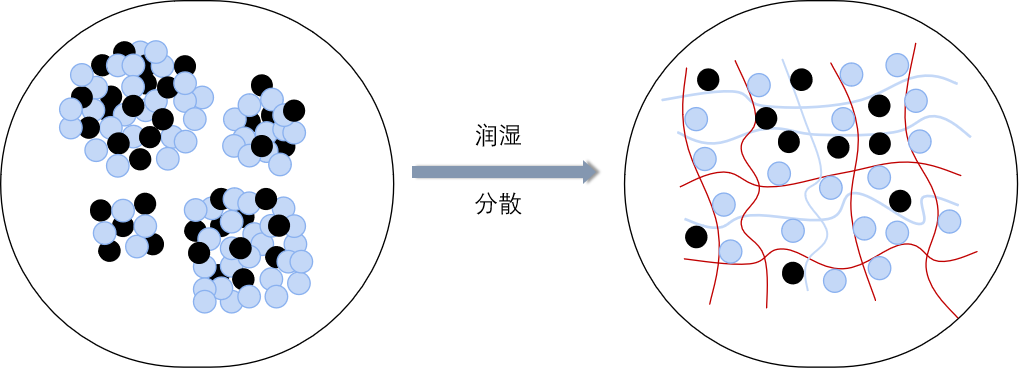

The core efficacy of Sparsux216 stems from its precisely designed molecular structure. The product employs a multi-amino polyether polymer as its backbone, where the multi-amino anchoring groups strongly adsorb onto the surface of LFP particles, forming multiple firm bonds. The polyether segments of the main chain fully extend in the NMP solvent, constructing a robust steric hindrance layer that physically prevents the re-agglomeration of LFP particles. Simultaneously, saturated alkane compounds (fatty amines) exhibit amphiphilic properties in the NMP solvent and can effectively reduce surface/interfacial tension through directional alignment.

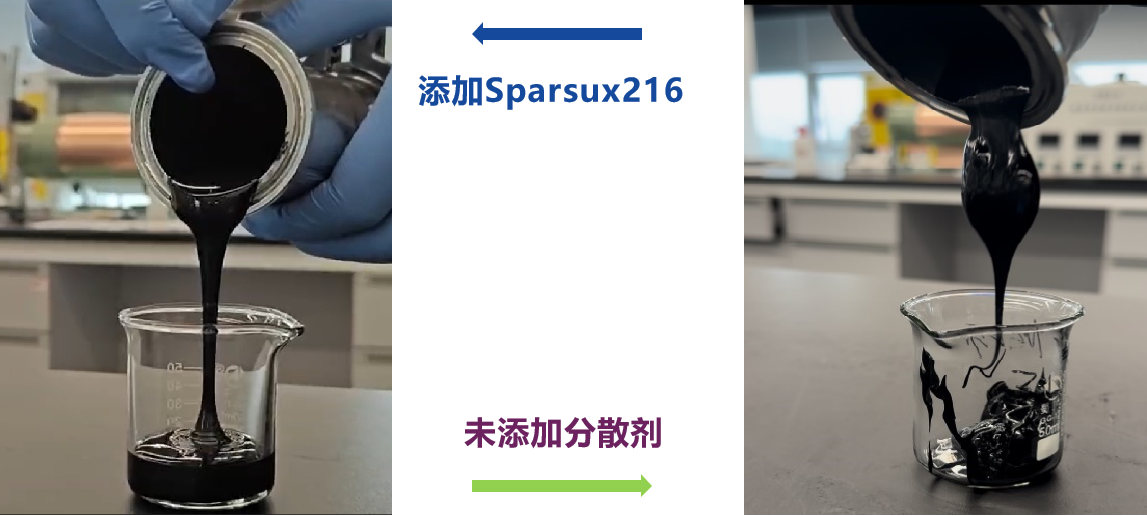

Based on the above mechanism, Sparsux216 delivers transformative process improvements in practical applications. Firstly, it significantly reduces slurry viscosity and suppresses its rebound over time. Relevant data shows that under a slurry solid content of 68%, adding just 0.2% of Sparsux216 can reduce viscosity from tens of thousands of mPa·s to the range of 6,000–9,000 mPa·s, maintaining stability even after 24 hours of static storage without gelation. Effective viscosity control makes it possible to increase slurry solid content by 5%–8%, directly reducing solvent usage and subsequent drying energy consumption.

Secondly, its exceptional dispersion effect greatly improves the processing performance of electrode sheets. Electrode sheet flexibility tests show that sheets using Sparsux216 remain crack-free even at smaller winding diameters. This translates directly into a major breakthrough in the coating process—enabling stable coating with an areal density exceeding 460 g/m². Compared to systems without dispersants, this significantly enhances the volumetric energy density and production capacity of batteries.

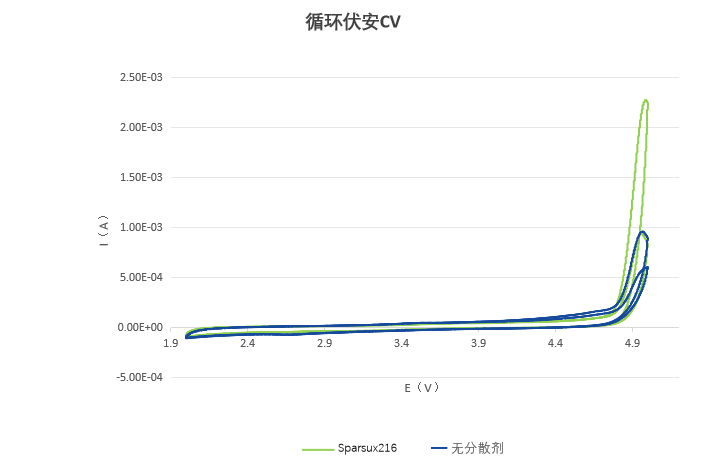

An excellent dispersant must not only improve processes but also be harmless or even beneficial to the final electrochemical performance of the battery. Comprehensive testing indicates that Sparsux216 exhibits outstanding electrochemical inertness. Its cyclic voltammetry curves almost overlap with those of the dispersant-free state, indicating that it does not introduce additional side reactions.

The value of technology lies in its broad applicability. Sparsux216 demonstrates significant and consistent viscosity reduction and stabilization effects across different LFP materials. This strong material compatibility allows it to be seamlessly integrated into various existing positive electrode slurry preparation processes (solid-phase/liquid-phase methods). It only needs to be added during the conventional glue preparation stage, requiring no modifications to core production lines, greatly reducing customer adoption barriers and upgrade costs.

Against the backdrop of the industry's pursuit of ultimate performance, focusing on the underlying material interface remains the core driver for battery manufacturing to advance to the next stage. MANST's Sparsux216 dispersant, through ingenious molecular design, fundamentally dismantles the agglomeration bottleneck of LFP. It provides a concise and efficient solution for the stable manufacturing of high solid content, high areal density electrode sheets.

NO.3, Zhukeng Third Industrial Zone, Jinniu East Road, Pingshan District, Shenzhen

0755-89369630

400-822-5968

brand@sz-manst.com